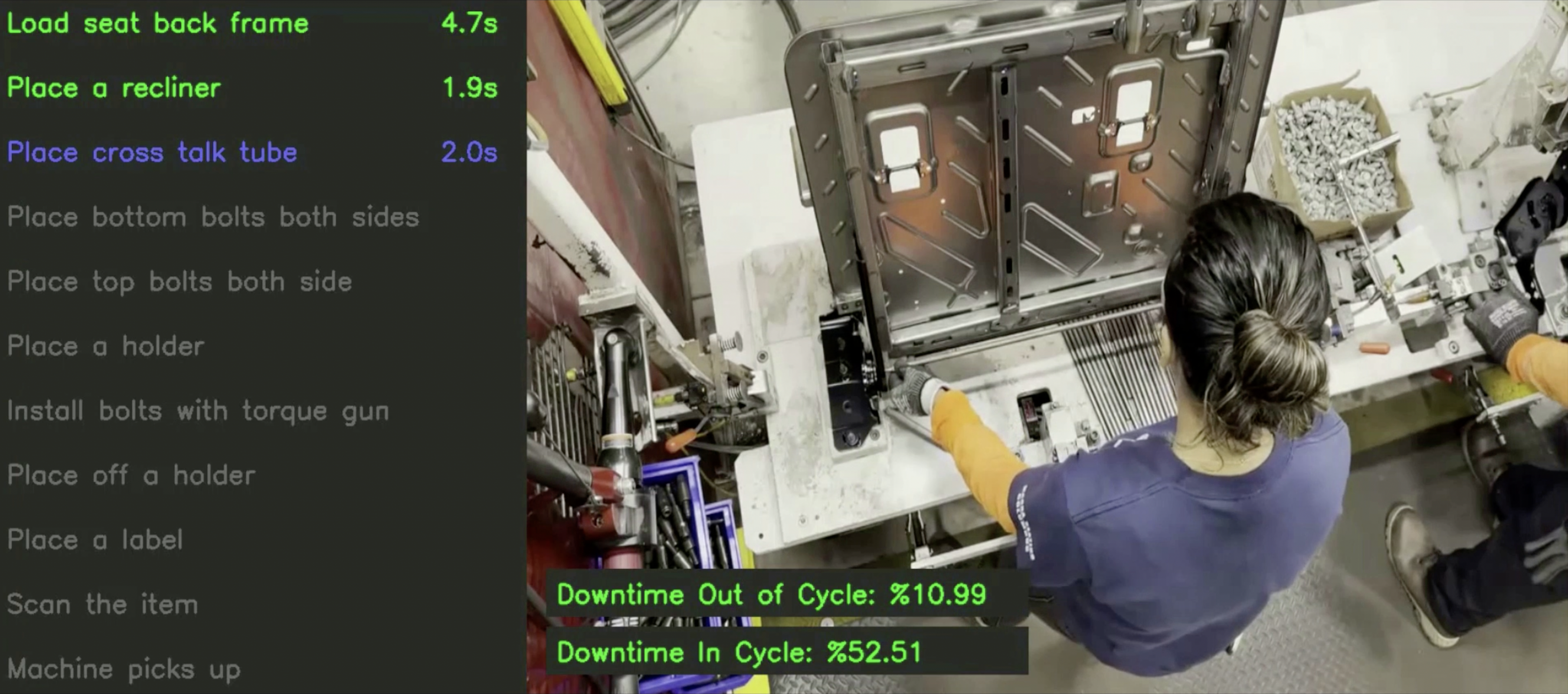

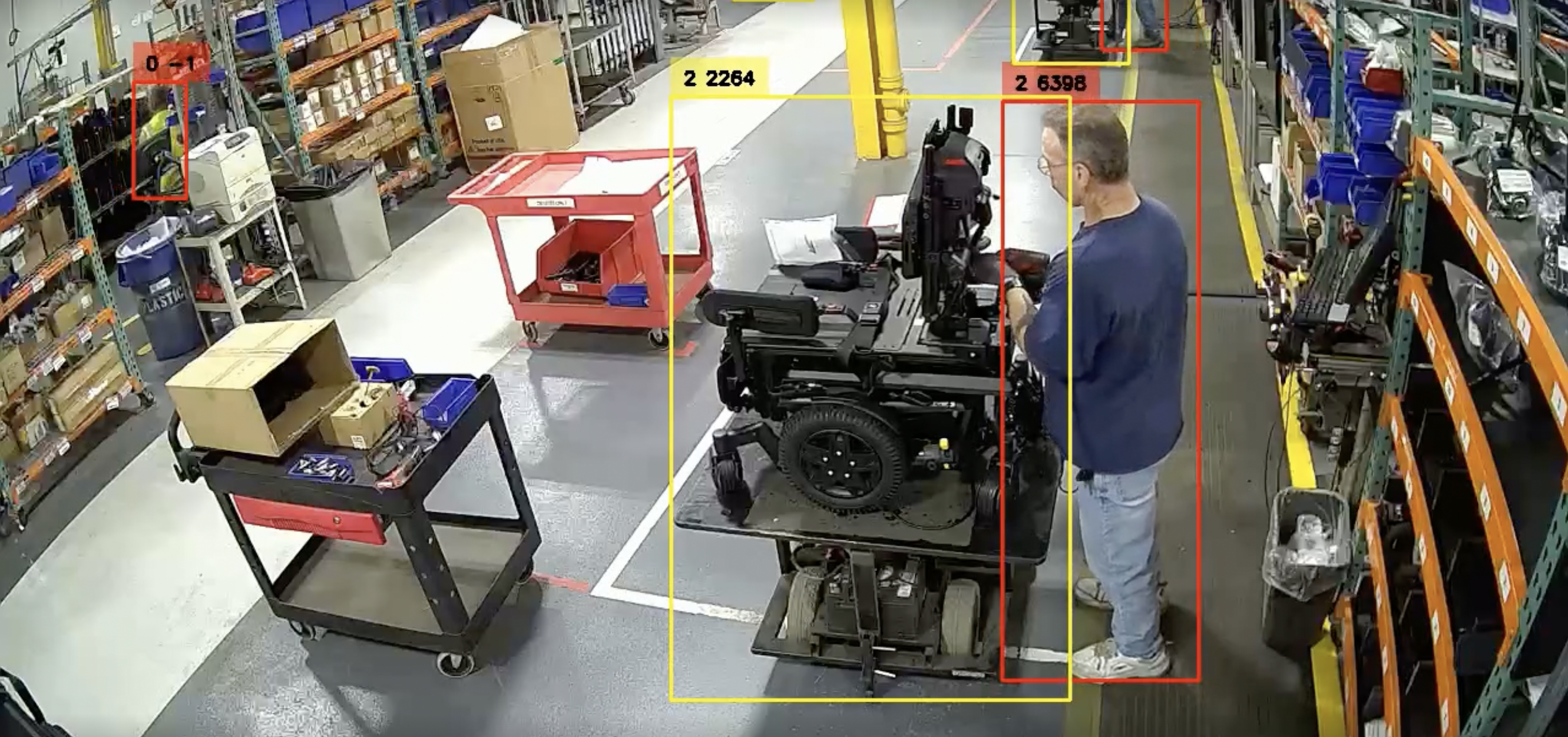

i-5O vision can validate your complex manufacturing processes following standard work instructions. For example, using live-streaming video data, our system can detect the precise alignment of panels, secure placement of clips, and accurate fastening of bolts to the vehicle. It catches errors as they occur, eliminating high rework costs. If errors are discovered late in the process, it may require disassembling the product, reworking, or even scrapping the entire unit. This results in wasted materials, labor, and time. Early error detection allows for immediate corrective actions, reducing the need for costly rework and minimizing production waste. This ensures that the product is built correctly from the start and thus gives you higher product quality and profitability.