Successful AI Transformation in Manufacturing

A successful AI transformation for a manufacturer consists of the implementation of AI at a scale that has a significant and continuous positive impact on the business. Given the haphazard way that manufacturers typically approach AI transformation today, this is rarely achieved. The manufacturers that have been the most successful at scaling AI within their organizations have been the ones that have selected simple use cases to quickly deliver ROI.

Common Pitfalls in AI Implementation

While the initial implementation may not be perfect, it gives the manufacturer a tangible win with AI and the confidence that they can continue scaling the technology. The manufacturers that are the least successful at scaling AI are the ones that approach AI with the attitude of ‘let’s find the most challenging use case in the organization because if the AI works in that use case it will work across our entire operation.’ While this sounds quite logical, it is a recipe for failure because these are the use cases where AI costs are high and prone to delays.

Best practices for scaling AI computer vision

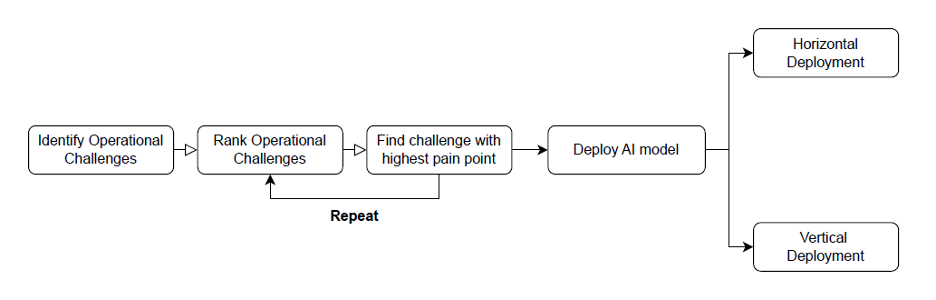

• Rank these operational challenges by how easy they will be to solve with AI computer vision

• Find an operational challenge that is the intersection between high pain and ease of solving with AI computer vision and rank all operational challenges in this way

• Deploy AI computer vision on the operational challenge where computer vision will be easy to deploy and deliver high impact to operations

• For this phase, it is important to keep the initial deployment simple to be able to deploy and deliver ROI rapidly. The AI deployment does not have to be perfect to deliver ROI as having AI computer vision is already a significant upgrade from the current process

• With this initial success, the manufacturer now has two options. The first option would be a horizontal approach to scale the AI computer vision deployment across the exact same process in all of its lines and plants. The second option would be a vertical approach to scale the AI computer vision system to new processes within the same line or plant. The horizontal approach is much lower risk and faster to generate ROI but will require the deployment of physical tech infrastructure such as high-speed internet and power lines into new facilities. The vertical approach will typically result in a slower rollout of AI, which is a much higher risk, but will allow the manufacturer to build out a fully `Smart` factory

Value Creation

Creating value with AI computer vision in a manufacturing enterprise should be an easy task with proper knowledge, planning, stakeholder alignment, resource allocation, and goals. To guarantee successful AI adoption, meet with our experts at i-5O, to book a customized use case analysis.