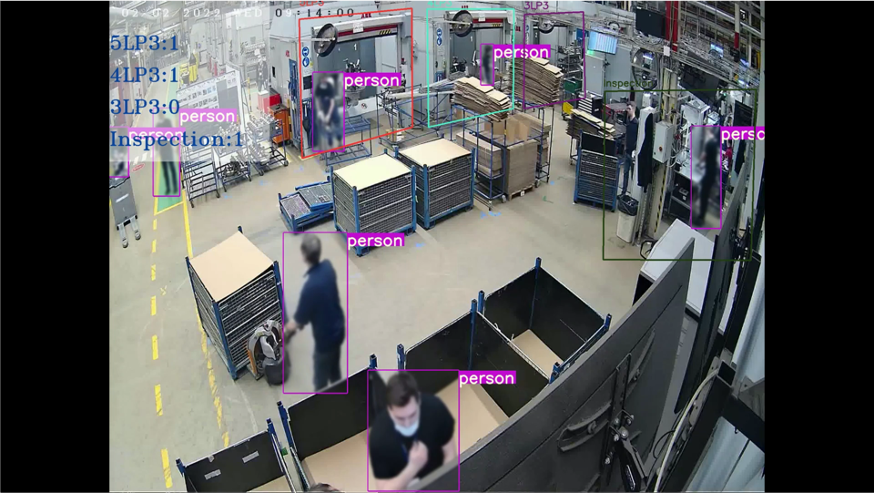

Time and motion studies have been common practice in manufacturing since the 1950s. They are used for measuring labor productivity in manufacturing with data gathered to improve production operations. However, the current manual methods of conducting time and motion studies have significant flaws that result in inaccurate data being generated. Using computer vision is a far superior technique for conducting time and motion studies as the data is much more accurate and a true reflection of the production environment.