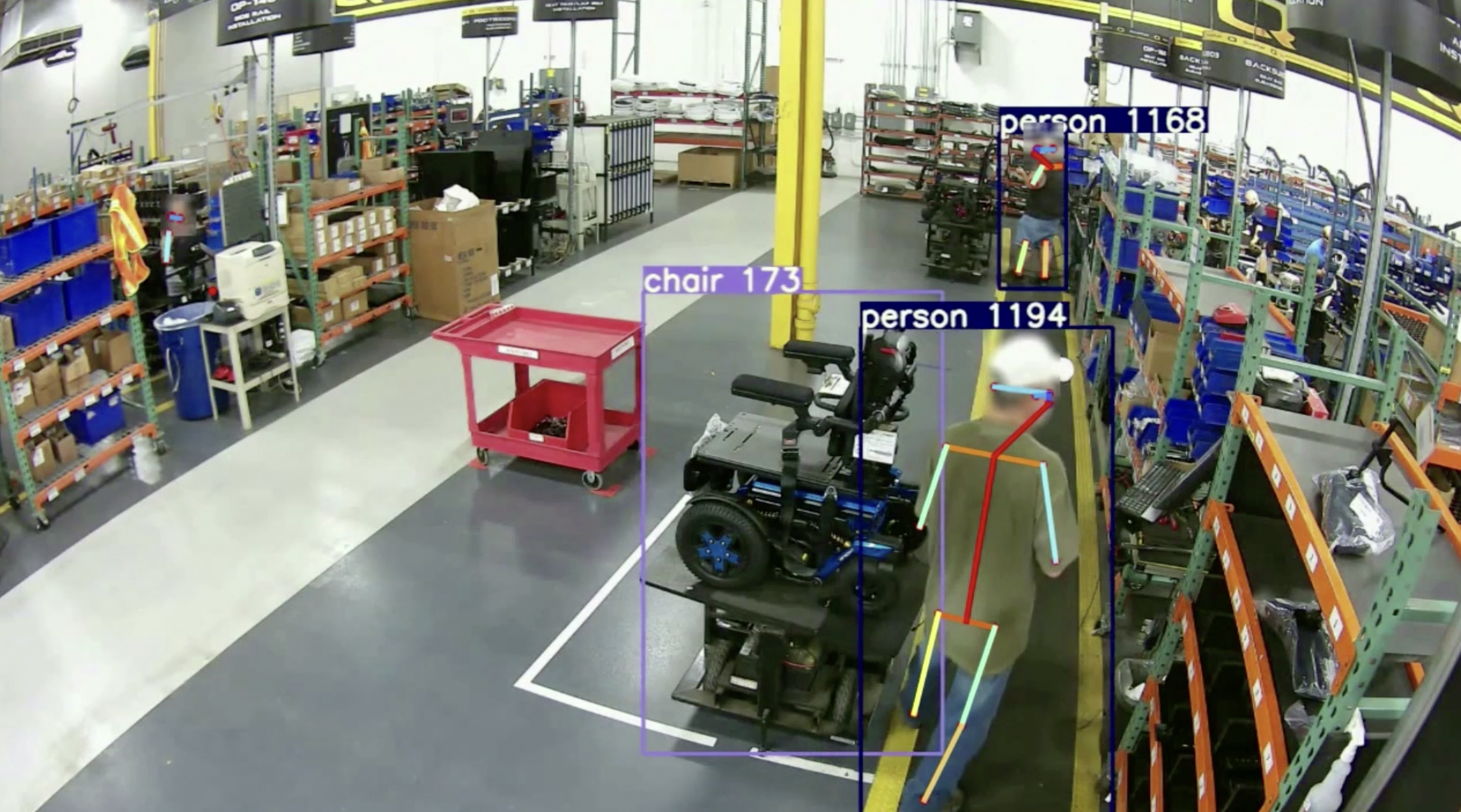

Industry Overview

Propelled by advancements in technology, a growing aging population, and increased awareness about mobility assistance, the power wheelchair industry has witnessed remarkable growth in recent years. This market is globally estimated to be valued atUSD 3.88 Billionin 2024 , and is expected to grow at a Compound Annual Growth Rate (CAGR) of 10.76, reaching USD 6.47 Billion by the year 2029. To cater to this growing demand, key players have been expanding their manufacturing capacity and investing heavily in research and development. However, there are a number of manufacturing challenges faced by the industry. Recent advancements in artificial intelligence have the potential to resolve these issues and aid power chair manufacturers in their operations.